|

Photo: Stockfile/FIS

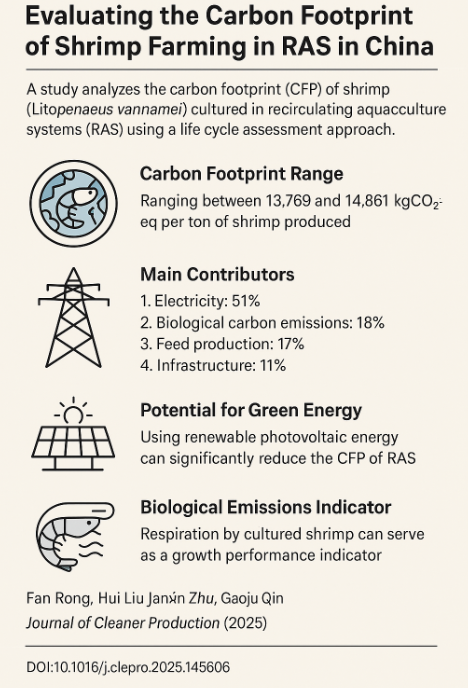

Evaluating the Carbon Footprint of Shrimp Farming in Recirculating Aquaculture Systems (RAS) in China

CHINA

CHINA

Tuesday, April 29, 2025, 08:00 (GMT + 9)

As global demand for sustainable seafood rises, aquaculture professionals worldwide are focusing their attention on technologies that can balance productivity with environmental stewardship.

A pioneering study by Fan Rong, Hui Liu, Jianxin Zhu, and Gaoju Qin provides critical insights into the carbon footprint (CFP) of shrimp (Litopenaeus vannamei) farming in Recirculating Aquaculture Systems (RAS) in China, the world's largest aquaculture producer.

Key Findings

Using a comprehensive "cradle-to-gate" life cycle assessment (LCA) approach, the study evaluated shrimp production across four RAS facilities and two culture modes. Results revealed that the CFP ranged between 13,769 and 14,861 kgCO₂-equivalents per ton of shrimp produced.

Major Contributors to Carbon Emissions:

-

Electricity Use: The largest source, accounting for 50.6% to 53.2% of total emissions.

-

Biological Carbon Emissions: Emissions from shrimp respiration made up 17.6% to 19.3%.

-

Feed Production: Constituted 15.9% to 18.1%, largely from raw material sourcing.

-

Infrastructure: Building materials contributed 9.5% to 11.5%.

These findings spotlight electricity consumption as the primary target for carbon reduction strategies in RAS operations.

The Role of Renewable Energy

An encouraging takeaway is the significant potential to lower the CFP through the adoption of renewable energy sources. Systems powered by photovoltaic energy reported drastically reduced emissions (572.52 kgCO₂-eq/t) compared to those reliant on coal-based electricity (7340.01 kgCO₂-eq/t).

This indicates that integrating green energy solutions can empower shrimp farms to achieve substantial carbon savings while offering more flexibility in site selection and operational planning.

Biological Emissions as a Performance Indicator

Interestingly, the study introduces the concept of biological carbon emissions (respiration by shrimp) as an important indicator of growth performance. Higher ratios of biological emissions relative to total CFP suggest greater carbon intensity and potentially lower farming efficiency.

Infrastructure and Farming Intensity

The research also highlights the often-overlooked role of infrastructure in shrimp farming's carbon profile. Intensive RAS systems, unlike traditional pond-based farms, require substantial materials like steel, concrete, and insulation—components that must be considered in sustainable aquaculture planning.

Furthermore, farming intensity—stocking density and management practices—has a direct impact on the carbon footprint. Overcrowding, beyond optimal culture densities, can lead to slower growth rates, longer farming durations, and ultimately, higher emissions.

Policy and Industry Implications

Given China's global leadership in aquaculture, this study serves as a call to action for policymakers and industry leaders. Encouraging energy-efficient systems, green infrastructure, optimized feed formulations, and biological performance monitoring will be crucial steps in promoting the green transition of aquaculture.

These findings support China's national policy for “Energy-saving and Emission-reduction Aquaculture”, offering a scientific foundation for shaping a more sustainable blue food system.

About the Study:

This article is based on research by Fan Rong, Hui Liu, Jianxin Zhu, and Gaoju Qin, published in the Journal of Cleaner Production (2025). Full paper available at DOI: 10.1016/j.jclepro.2025.145606.

editorial@seafood.media

www.seafood.media

|