|

Designed to operate within freezing cabinets at temperatures as low as -30°C, the system solves a critical industry bottleneck

Carsoe Launches High-Tech 'Buffer Warehouse' to Revolutionize Frozen Logistics

(DENMARK, 11/22/2025)

(DENMARK, 11/22/2025)

The CS3015 System eliminates manual handling in sub-zero conditions with intelligent automated storage

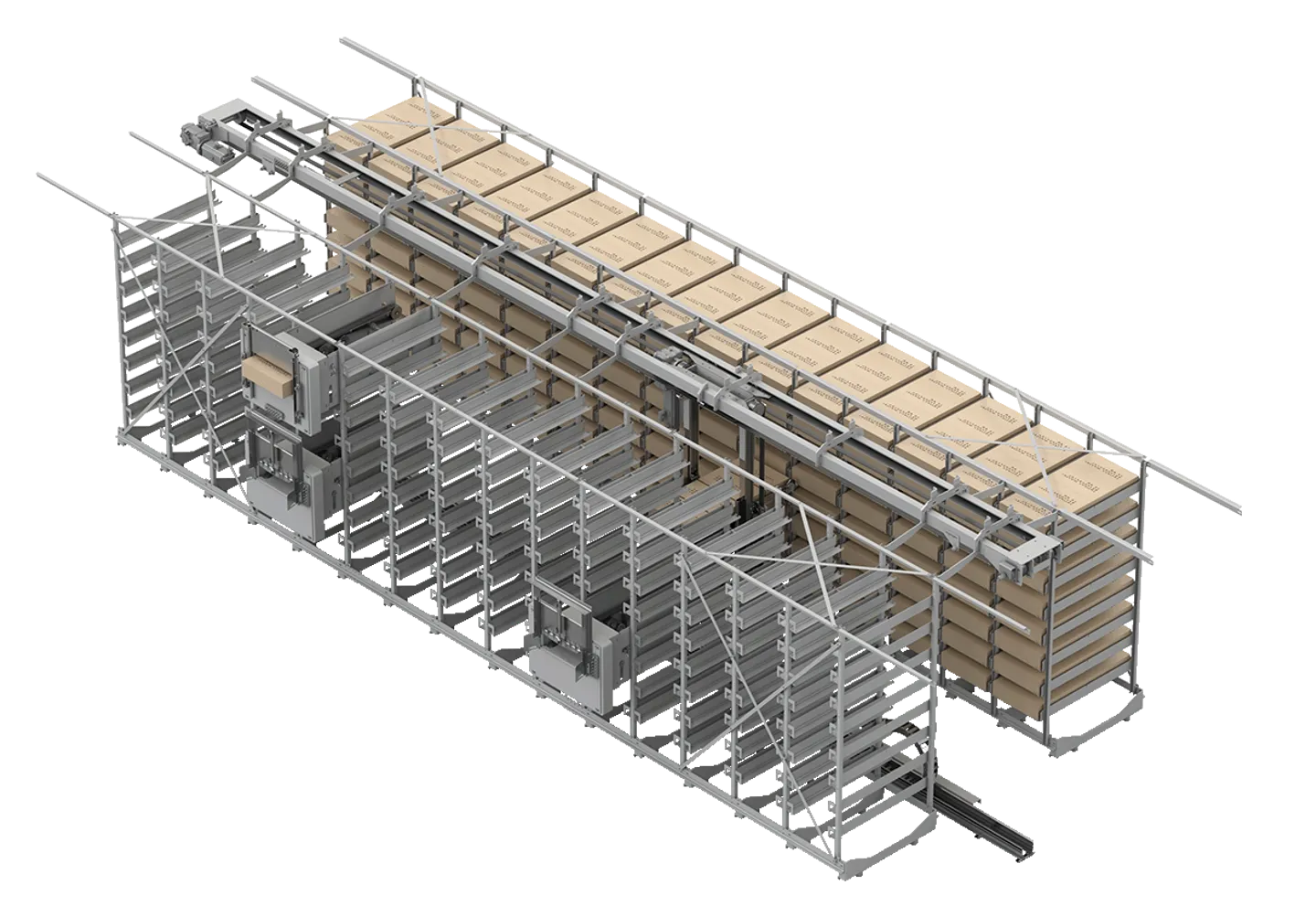

AALBORG – Leading food processing equipment manufacturer Carsoe has unveiled the Crate and Box Buffer System CS3015, a fully automated logistics solution designed to optimize inventory management in extreme production environments. This advanced ASRS (Automatic Storage and Retrieval System) functions as a specialized internal warehouse, bridging the gap between processing lines and final palletizing.

Designed to operate within freezing cabinets at temperatures as low as -30°C, the system solves a critical industry bottleneck: the inefficiency and safety risks of manual sorting in deep-freeze conditions. By automating the buffering process, Carsoe ensures that high-volume producers—such as those in the seafood processing and large-scale food manufacturing sectors—can maintain continuous throughput without downtime.

Automated Warehouse Concept

The CS3015 acts as a temporary warehouse integrated directly into the factory floor. In standard production lines, crates often accumulate faster than they can be palletized, leading to clutter and manual intervention. Carsoe’s solution provides a high-density, vertical shelving system where products are organized and held until they are ready for dispatch.

"Carsoe specializes in designing fully integrated processing lines where the buffer system works seamlessly with the complete factory layout," the company explained. This seamless integration ensures continuous product flow and minimizes the time sensitive frozen goods spend outside of controlled environments

Intelligent Sorting and Retrieval

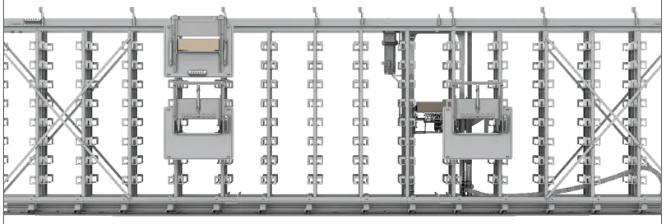

The system utilizes a smart logic flow to manage inventory without human hands:

-

Input Scanning: A label scanner at the infeed conveyor identifies every box before it enters the warehouse.

-

Automated Allocation: The system determines the exact shelf location within the warehouse based on parameters such as production batch, grade, or product type.

-

Buffering: Boxes are mechanically picked and placed on shelves, optimizing space and organization.

-

Output: Once the warehouse contains enough boxes of a specific grade to fill a full pallet, the system automatically retrieves them and moves them to the palletizing area.

Engineered for Extremes

While standard automation often fails in harsh environments, the CS3015 is specifically engineered for the freezing cabinet. Its ability to operate reliably at -30°C makes it an ideal solution for the seafood industry, where Carsoe has established itself as a leader in both land-based and onboard trawler processing solutions.

Key Advantages

Implementing the Crate and Box Buffer System CS3015 offers distinct operational benefits:

-

Integration into the processing line: Connects processing and packaging into a single streamlined flow.

-

Efficient storage and sorting: Automated logic maximizes space utilization within the warehouse.

-

Improved productivity and flow: eliminates bottlenecks and stops caused by manual handling.

-

Reduction of manual labor: Removes workers from strenuous tasks in sub-zero temperatures.

-

Higher precision and quality: Ensures accurate sorting and reduces damage to crates.

By treating the buffer zone as an intelligent "hotel" rather than simple storage, Carsoe aims to help manufacturers optimize their yield and secure their cold chain from start to finish.

editorial@seafood.media

www.seafood.media

Information of the company:

|

Address:

|

Mineralvej 6-8

|

|

City:

|

Aalborg Øst

|

|

State/ZIP:

|

(DK-9220)

|

|

Country:

|

Denmark

|

|

Phone:

|

+45 98 24 26 24

|

|

E-Mail:

|

info@carsoe.com

|

More about:

|

|

|

|