|

Photo: Skjermdump sluttrapport/fhf

New Automated Mackerel Sorter Promises Higher Value for Pelagic Producers

(NORWAY, 12/15/2025)

(NORWAY, 12/15/2025)

Prototype Successfully Weighs and Grades Large Mackerel, But Feeding System Needs Refinement

.png)

Photo: Skjermdump sluttrapport/fhf

A significant step toward more precise sorting of large mackerel has been achieved with the development and testing of a new industrial pilot. The prototype, created by MMC First Process, focuses on automated post-sorting to increase value creation in pelagic consumption factories by improving the accuracy of grading for mackerel over 600 grams (G6).

Traditionally, mackerel is sorted by diameter, while its sale and pricing are based on weight. This inconsistency often results in larger, more valuable fish being assigned to the incorrect weight group. For the highly-priced G6 mackerel, this missorting leads to substantial losses for producers. The new project was established to develop an automated technology to correct this costly inaccuracy.

Photo: Skjermdump sluttrapport/fhf

How the Prototype Works

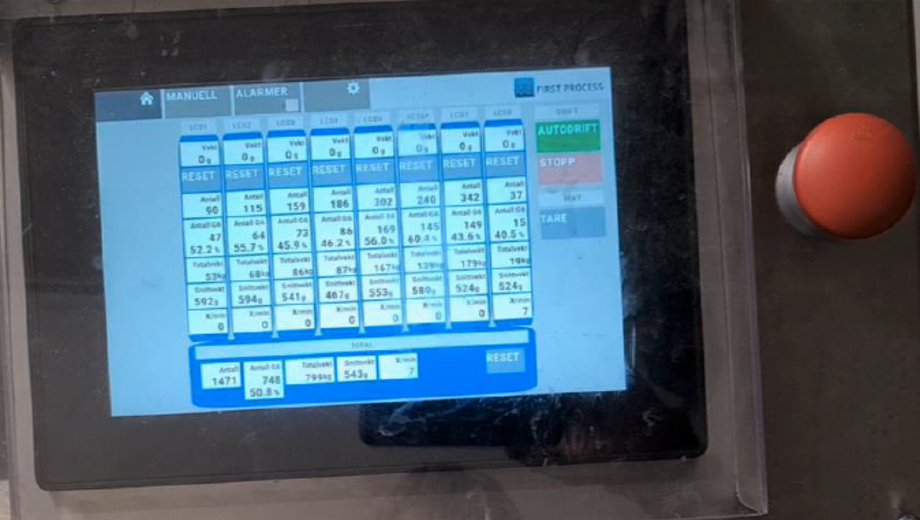

The pilot machine is engineered with a receiving belt and a grading unit comprising eight parallel tracks. Fish are singulated—separated into single units—using three belts with increasing speed before passing over weighing zones equipped with load cells. Once the weight is recorded, pneumatic sliding flaps guide the fish into the correct category. The entire system is managed by a PLC solution featuring a calibration function and a visual control panel. The machine's construction uses hygienic, stainless material, adhering to the stringent requirements of the food industry.

Photo: Skjermdump sluttrapport/fhf

Weighing Technology Proves Sound

Full-scale production tests in 2024 demonstrated that the weighing function and the core sorting technology operate as expected when the feed is adequately controlled. The machine’s weighing accuracy and component precision were deemed acceptable. Capacity measurements confirmed that the system could achieve the target throughput of 40 fish per minute per slot.

However, the major challenge identified was the process of feeding and singulating the fish.

-

The feeding mechanism failed to provide a sufficiently even distribution of fish across all eight slots.

-

Fish frequently entered the weighing zone in pairs or at excessively short intervals.

-

This resulted in significant missorting, exceeding 15% during the full-scale tests.

Photo: Skjermdump sluttrapport/fhf

Potential for Further Development

Despite the feeding issues, the technology holds great potential for increased value creation. Calculations indicate that a stable and precise G6 grader could significantly increase the proportion of the largest fish that are correctly sorted, subsequently reducing the need for costly manual post-sorting.

.png) The project team recommends the development of a new or improved feeding solution that can guarantee: The project team recommends the development of a new or improved feeding solution that can guarantee:

-

100 percent singulation to the weighing zone.

-

Even distribution of fish across all tracks.

-

Stable capacity and predictable sorting accuracy.

Lars Lovund, FHF - Fiskeri - og havbruksnæringens forskningsfond (Norwegian Seafood Research Fund) manager, summarized the findings: "This project shows how demanding it is to automate the handling of pelagic species, but also that there is potential for more precise sorting based on individual weight. With improved feeding technology, this can contribute to higher value creation in the pelagic consumer industry. The technology can also be adjusted to size sorting of other species such as, for example, herring, if this is commercially interesting.”

editorial@seafood.media

www.seafood.media

Information of the company:

|

Address:

|

Fosnavåg

|

|

City:

|

Eggesbønes

|

|

State/ZIP:

|

(6092)

|

|

Country:

|

Norway

|

|

Phone:

|

+47 70 08 39 00

|

|

Fax:

|

+47 70 081660

|

|

E-Mail:

|

office@mmc.no

|

More about:

|

|

|

|